Fibre 3D Printer

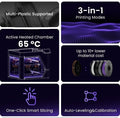

Strength of 900 MPa, 3 Printing Modes, Maximum Speed of 500 mm/s, 300 Large Volume, Smarter Workflow, Affordability, and Compact Design

Compromise is not an option when working parts are required.

With the First Fibre 3D Printer's up to 900 MPa tensile strength, you can make end-use parts that are comparable in weight to aerospace-grade aluminum. Your prints can now be used outside of the workbench for everything from mission-critical brackets to heavy-duty jigs.

Use Mask tools to specify fiber placement zones, modify support structures with blockers and enforcers, and preview prints in great detail. Take advantage of open-format G-code export, adjustable parameter adjustment, and support for STL, STEP, OBJ, and more.